Ruma Products

Ramex proud to be the official representative of Ruma Products in Scandinavia and UK.

Ruma is an 85-year old rubber company based in Hoogeveen, Holland. Ruma design, test, manufacture and supply elastomeric products to many industries including the petroleum industry where they are mostly known for their Oblique swelling seals.

For the past 5-10 years there has been an increase in demand for swellable elastomer seals for use in Oil and Gas wells. Swelling seals have proven to be useful in creation of compartments in long open-hole liner systems as well as for fracturing formation while also being a considerably cheaper and simpler alternative to the traditional mechanical packers.

Fun Fact

Did you know that during the second world war swelling elastomers were used by the military on aircraft fuel tanks as a self-sealing mechanism?

Ruma Products Hoogeveen, Holland

Why chose Oblique?

Ruma Oblique products are certified to ISO-29001 (as well as ISO 9001 and ISO 14001) for swelling seals.

The knowledge required to do this and the test facilities are all in-house as is the research and development programs.

Ruma’s laboratory is one of the best in the world on swelling elastomer technology and has the most extensive selection of elastomer compounds and combinations of these.

The first water swelling elastomer (E-zip seal) was developed by Ruma laboratory for PDO Oman

The first oil swelling seal used on the NCS was developed by Ruma for Easywell/Hydro in 2000.

“Ruma Products is unique in the industry in being able to design and compound its own elastomers, design its own swelling articles made from those elastomers and then have its own facility to manufacture these articles”.

Our Goal

To Be the best in the world, with the best products and the best prices.

How do we achieve this? QUALITY 100%

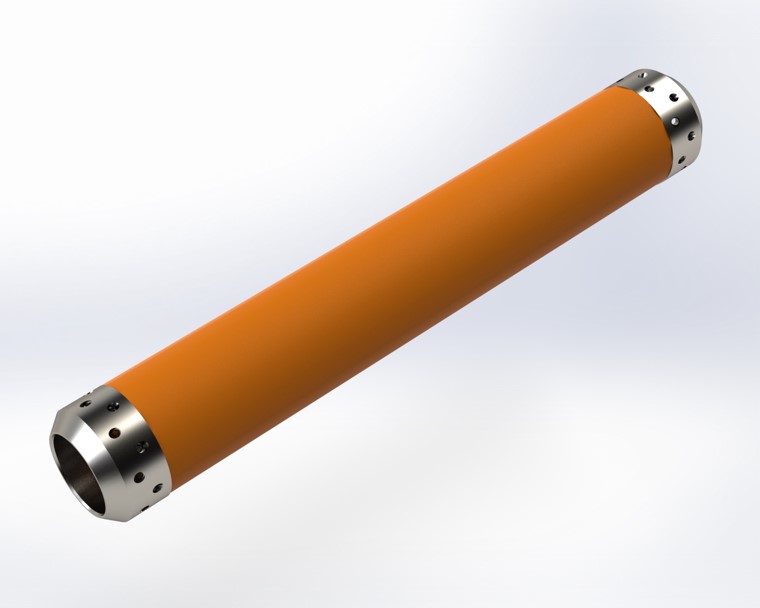

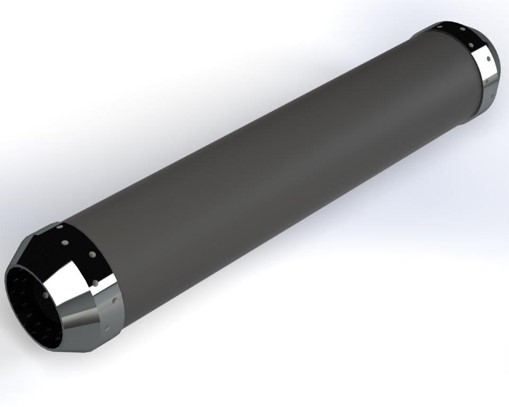

Oblique swelling seals

Ruma Oblique swelling seals are colored for easy identification.

Blue swells in water. Red swells in oil. Black is a hybrid elastomer which means it will swell in both oil and water.

Swellable elastomer seals product overview

Product Range 2018. Click to download »

Q-Seal

Available in 1ft lengths up to 44 ft versions to fit most common OCTG sizes and well hole size combinations with the metallurgy to suit the

Q-Stat

A made to measure slip on product developed for ease of field installation.

Available in either 3 ft. 1,5 ft. or1ft. lengths to suit water and oil swelling applications up to a temperature of 200 C and as low as 10 Celsius. The seal is locked into place on the tubular with running guides equipped with standard Grub screws to hold the unit firmly to the Base Pipe. Available to fit onto all commonly used API pipe sizes and an Outside Diameter to suit the application.

Q-Stat CL

A made to measure slip on seal swelling seal with up to 5 Control line penetrations developed for ease of field installation and control line alignment.

Available in 3 ft. lengths to suit water and oil swelling applications up to a temperature of 200 C and as low as 10 Celsius. The seal can be fitted with easy to install penetration blockers for applications that use less than 5 penetrations and has two locking running guides as well as a control line locking system.

Q-stop

Designed to be a short easily slipped onto a liner system to create compartments when used in combination with ICD’s helping stop sand migration between compartments.

Has a limited differential pressure rating. Available to measure to suit any combination of Hole and liner sizes and be available in

Water or Oil swelling Elastomers.

Q-sagd

A

Available in lengths up to 3ft with single or dual integral running guides to fit all common OCTG and well hole size combinations with metallurgy to suit the well conditions.

Q-warp

A

Available in lengths up to 3ft with dual integral running guides to fit all common OCTG and well hole size combinations with metallurgy to suit the

Non-swelling

A wide range of moulded products developed and designed to suit specific conditions (i.e. abrasive resistant, chemical resistant, temperature resistant, pressure)